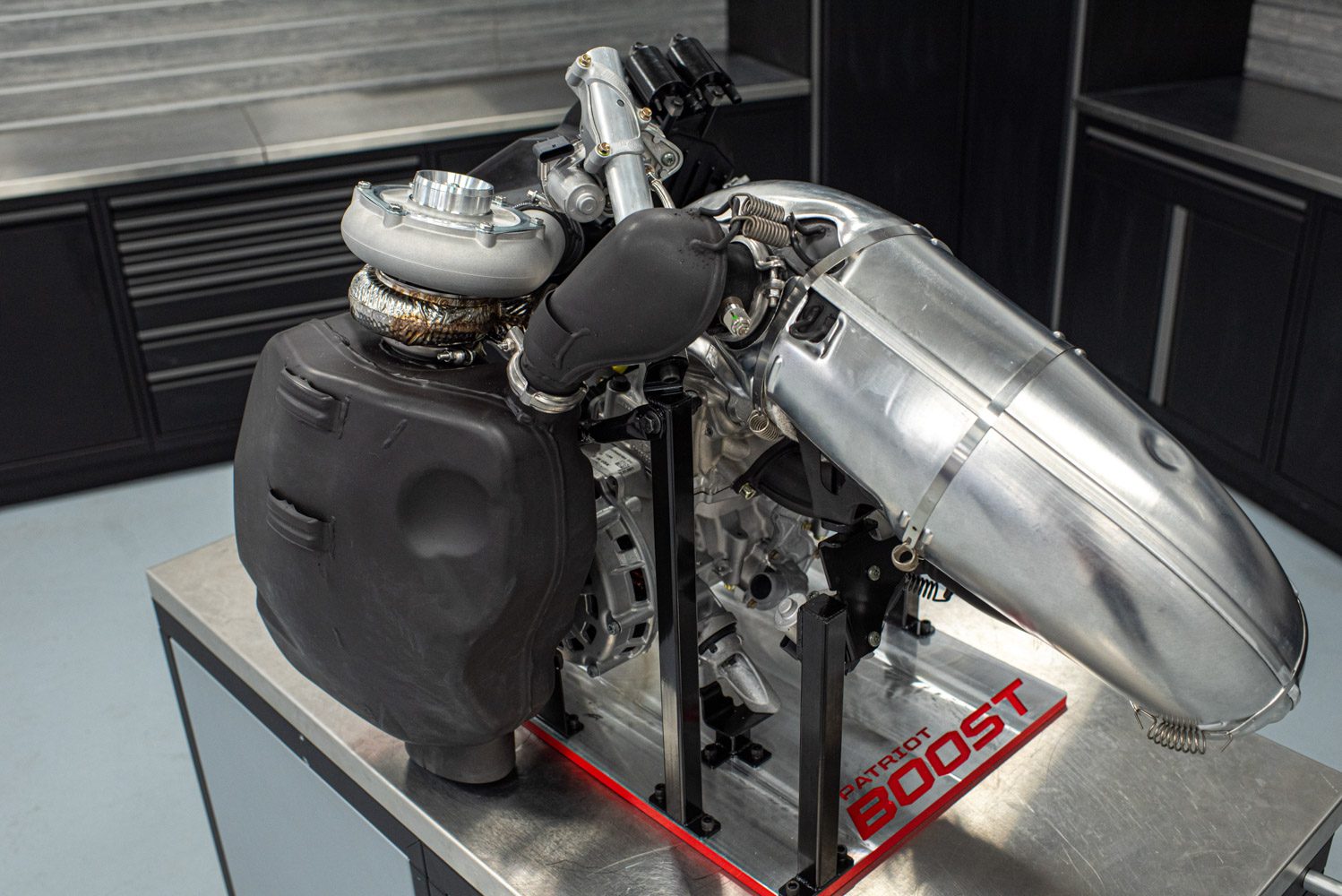

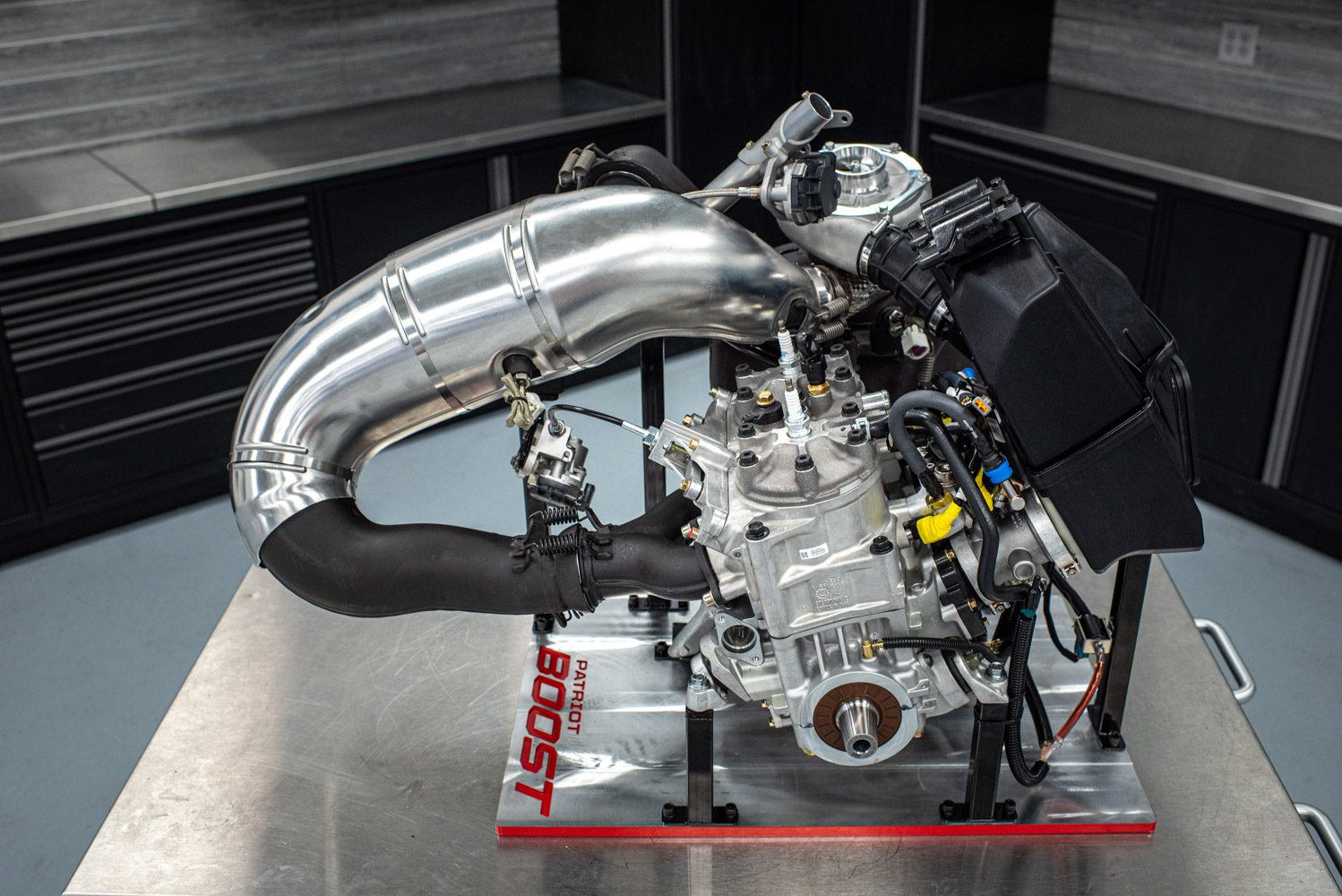

Polaris calls it the most powerful two-stroke engine ever produced! The order given to the Polaris engineers was simple: we want power everywhere, not just at the top of the mountain. Well, mission accomplished! This new Polaris Patriot BOOST engine uses virtually all the same components as the Patriot 850 engine: the same crankshaft, the same ball bearings and the same connecting rods. Only the pistons are different to receive the turbo boost. Did we say boost? Yes, yes, a lot of boost: 9 pounds of maximum pressure injected into the 850. We are told that the power at sea level is increased by 10% compared to the atmospheric 850, and this power is maintained to reach 50% more power at 10,000 feet!

Let’s talk numbers

Let’s assume a naturally aspirated 850 Patriot at 165 horsepower, which is conservative, 165HP X 10%, we get 16.5 more horsepower, which puts the new thoroughbred at 181.5 HP at sea level!!! WOW! Polaris presents us with this new system with the same reliability, control and no lag time (LAG).

This new turbo is located vertically directly on the muffler and is presented to us with a 40% lighter weight compared to the turbos available on the market. Another noteworthy factor is that the positioning of the turbo in relation to the engine intake is very close, which allows for a very short charge tube, thus improving response. Polaris also owns the design that manages the exhaust and the relief valve.

Polaris Patriot BOOST – Smart boost Design: Relief valve

The American manufacturer presents us with a brand new way to manage turbo pressure. Usually, the wastegate is located directly on the turbo and opens when the pressure is too high. It lets air from the calibrated hose escape through a door adjacent to the turbine, reducing the revolution of the compressor that pushes pressurized air into the engine.

To achieve a faster response, the engineers designed a very different pressure management concept. The relief valve is separate from and parallel to the turbo, providing a direct link between the calibrated pipe and the resonator. When the need to reduce pressure arises, the relief valve opens to direct some of the internal pressure from the calibrated pipe to the resonator. In this way, the rotational speed of the turbo is reduced which, in turn, reduces the pressure pushed into the intake system.

There’s no doubt about it, Polaris has broken the 180 horsepower barrier for a two-stroke engine, and this is the first time in history that a production snowmobile has ever been built! Congratulations!